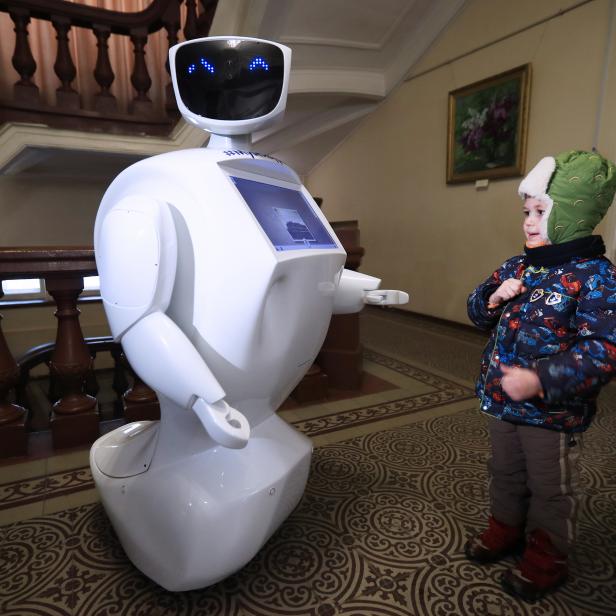

GettyImages/Vladimir Smirnov

Cobots: Robots with a Human Twist

What Does an Integrated Future of Man and Machine Look Like? Read on about the growing trend towards cobots that work in harmony with humans is transforming robotic use worldwide.around the world.

Working robots are typically big, simple, and strong. They are large preprogrammed units working in dangerous and dull jobs, such as precision spray painting or spot welding in car manufacturing. But the growing trend towards collaborative robots, or cobots, that work in harmony with humans is transforming robotic use worldwide.

The fact is that most industrial robots were not designed to cope with unpredictable human environments – workplaces made unpredictable by human behavior. By shrinking robots down to desktop size and embedding them with sensors and AI, the next generation of cobots will feel our presence, learn from us, and integrate with us better.

Lightweight and portable cobots can work in less space and share it with people rather than being caged off. Decreasing costs for robotic systems make them more affordable to small businesses, and their ease of set up and programmability makes cobots simple to deploy.

But what exactly is a cobot? The definition of cobots includes exoskeletons made of tough textiles that provide support for the injured or disabled, and software-based virtual assistants or chatbots for home or online services. These intelligent helpers will become an extension of mobile devices, with their operating software and security patches updated from the internet.

Typical industrial uses for cobots include packing, stacking, machine tending and assembly. More specialized functions include use in clean rooms or biomedical facilities where humans might contaminate samples, surgical procedures, picking plants, making tea and coffee, or even creative outlets such as painting or photography.

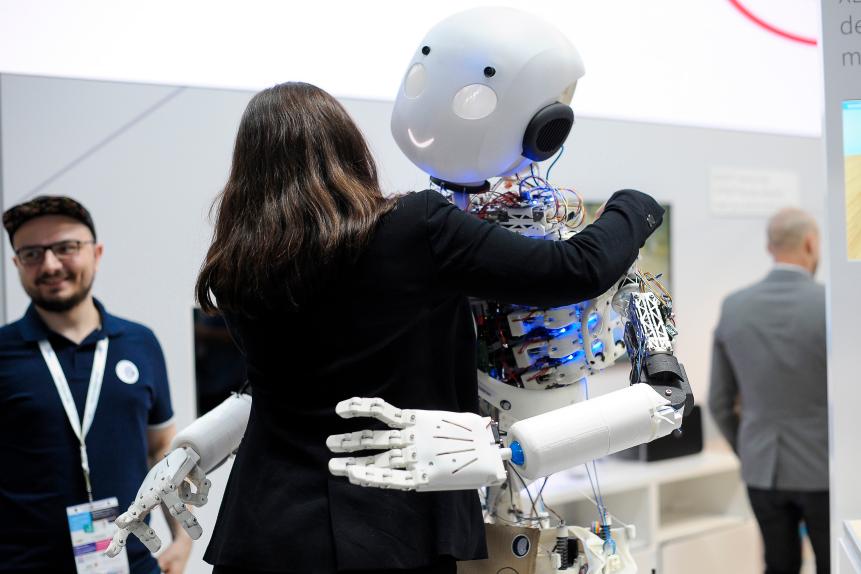

GettyImages/NurPhoto

Although the collaborative robot is relatively novel, the initial concept was invented in 1996 at Northwestern University in the US. A cobot patent was filed in 1997. It detailed “an apparatus and method for direct physical interaction between a person and a general-purpose manipulator controlled by a computer.” The idea of robotic feedback was also built-in so that cobots would redirect or steer motions that originate with the operator through physical guidance.

Still, the suspicion persists that introducing robots lead to job losses. Some forecasters predict that 20 million manufacturing jobs will be lost worldwide by 2030. There are concerns about safety and integration in shared workflows – if robots have to slow down or stop to avoid hitting people there are questions about the expected productivity gains.

What big companies such as Germany’s Mercedes-Benz discovered was that robots alone were not agile enough to keep pace with the demand for customized products. Human-robot collaboration was identified as the optimal strategy.

“When we have people and machines cooperate, we’re much more flexible and can produce many more products on one production line,” said head of production planning, Markus Schaefer. “The variety is too much to take on for the machines.”

The future of cobot working is likely to change as newer interfaces and ways of interacting are developed. Voice commands are bound to be a feature as natural language processing systems become more widespread. Robotic movements and interactions will be controlled using non-invasive brain control interfaces.

Closer integration with machine learning and AI is inevitable to realize the benefits of elements such as voice control and machine vision. Unplanned changes to production and safer interaction with humans will then require a step-change in robot learning.

Cobots will learn directly from human interaction or even from virtual simulations that will help them to adapt to real-world situations. Open robotics platforms, such as Carnegie Mellon University’s ‘LoCoBot’ or Elephant Robotics’ ‘Catbot’ means that programmers can share the skills they have developed via the cloud.

Importantly, for household robots to gain traction then reinforcement learning – where environmental data is gathered to make more robust decisions – will be needed. Cobot carers such as ElliQ the companion robot, ceiling-mounted rail robots, or even IKEA’s robotic furniture, promise a benign future of cooperation.

Like any achievable technological dream, such as self-driving cars, their realization is imminent. Cobots and intelligent assistants will become standard in the same way that a car’s GPS or the smartphone did. Their integration into society will gradually become the norm.